Product Details

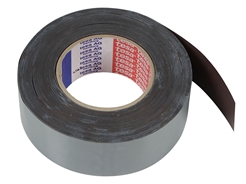

JemmSil™ CT1125 Release Tape, specifically designed for roller wrapping applications, features a unique, textured surface, which provides excellent release characteristics, and is ideal for use in extrusion coating and lamination, as well as hot melt and pressure sensitive applications.

As the most economical release solution, JemmSil™ CT1125 Release Tape consists of a special silicone coated fabric construction, which in addition to great release characteristics, provides good grip properties, as well as, making it a good choice for traction applications. JemmSil™ CT1125 Traction Tape is produced with a permanent solvent based rubber/resin adhesive system, which provides good adhesion to metal and other roller surfaces.

The JemmSil™ CT1125 is found in many applications including, printing, coating, lamination, extrusion, slitting and converting, JemmSil™ CT1125 Release Tape has proven to be an economical solution to release and grip applications.

Features

- Typically stocked in 2” wide rolls that are 36 yards long, however, custom widths are available

- Found in applications including: printing, coating, lamination, extrusion, slitting and converting

- Easy to install on-site

Technical Specifications

| Release Properties |

Fair |

| Traction Properties |

Good |

| Heat Resistance |

265°F |

| Wear Resistance |

Good |

| Hardness |

N/A |

| Adhesive Type |

Rubber |

| Surface Finish |

Smooth |

| Wall Thickness |

.24mm |

| Available Widths |

2" |

| Available Lengths |

27.5 yards |

| Liner |

No |

| FDA Compliant |

No |

Technical Data

| Adhesion to Steel |

7-10N/25 mm (30 oz/in) |

| Backing Material |

Glass Cloth |

| Color |

White |

Installation

Four Simple Steps for In-Plant Tape Installation!

- 1.

To get started, wrap your Jemmco tape one full rotation around the roller at the angle required to achieve your spiral. Make a mark on the second wrap where it meets the beginning of the tape.

- 2.

Lay the tape on a flat cutting surface and cut the tape at an angle from the marked point to the opposite corner of the beginning of the tape roll.

- 3.

If applicable, remove the liner at the start point and begin wrapping the tape at the edge of the roller.

- 4.

Wrap the tape around the roller - at even angles - without leaving any gaps or air underneath the tape.